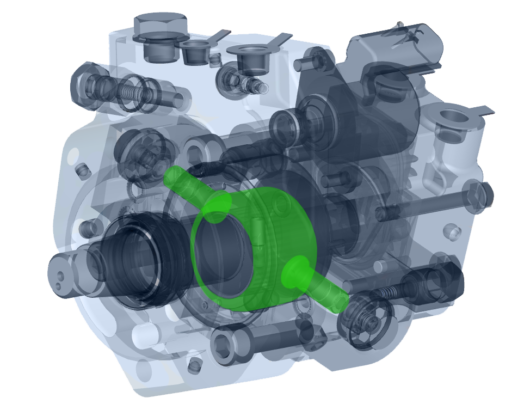

The two-piston DCR pump is based on a compact and modular design for easy integration, has low hydraulic and acoustical noise, features ultra-fast response times, and is biofuel and low-lubricity fuel compatible. It uses a patented eccentric drive pumping technology, with pressure-lubricated cam and bushings, for increased performance, efficiency, and benchmark durability. The Fuel Control Actuator (FCA) uses high-quality corrosion-resistant components and proprietary features to prevent large debris from entering the actuator, providing exceptional robustness for longevity and durability in harsh environmental conditions. The DCR can provide a max fuel delivery of 1,250 mm3 per revolution (25% more than a CP4.2), producing plenty of flow for worn injectors that have high return.

12 BOTTLE CASE

BOTTLE SIZE - 4 FL OZ

Hill Diesel Fuel Additive is your one step fix to all diesel fuel problems. Its full synthetic formula contains no alcohol, increases cetane, prevents water build up, prevents gelling to -40°, prevents algae growth and reduces smoking. This product is EPA Registered. Add 1 oz of Hill Diesel Fuel Additive to every 10 gallons of diesel fuel.

TECHNICAL SPECS -

FUEL STABILIZATION: Conforms to specifications (Mil-T-5624P and ASTM D 1655). Hill Diesel Fuel Additive controls gum and peroxide formation in all diesel fuels, stopping the formation of oxidation and asphaltenes. This is the highest standard of protection for any diesel fuel in storage, rated at over 3 years in hot and cold temperatures. (i.e. generators, motorhomes, heavy equipment, etc.).

ANTICORROSIVE PACKAGE: This technology prevents corrosion on fuel tanks and storage tanks above and below the fuel with the only Diesel Vapor Corrosive Inhibitor available.

Protects all metals as tested by ASTM D130 (received an A-1 rating) and by NACE (received an A rating).

SYSTEM CLEANING/HIGH TEMPERATURE DETERGENT: Hill Diesel Fuel Additive promotes better volumetric efficiency allowing for continuously clean spray patterns. This detergent guards against gum and varnish build up to free up sticky injectors. Hill Diesel Fuel Additiverestores the fuel system back to the manufacturers original specifications.

ANTI GEL/POUR-POINT DEPRESSANT: Adding Hill Diesel Fuel Additive into No. 2 Ultra Low Sulfur Diesel fuel effectively lowered the pour-point by -22°F

(from the base pour-point).

UPPER CYLINDER LUBRICITY: The new ULSD blends reduce the amount of lubricity in the fuel. Hill Diesel Fuel Additive has an additive that restores lost lubrication, which significantly improves the condition of the cylinder liner, piston, and piston ring (as tested by ASTM D7688).

WATER REMOVAL & PROTECTION: Hill Diesel Fuel Additive disperses water molecules allowing them to pass harmlessly through the fuel system and burn during combustion. Hill Diesel Fuel Additive prevents the bound water in the diesel/bio-diesel blends from settling on the bottom of the tank. This prevents microbial growth as well as stops asphaltenes from forming sludge which plugs and damages most filters (as tested by ASTM E1064).

CETANE IMPROVEMENT: Hill Diesel Fuel Additive increases cetane ratings by 4 numbers or 40 points based on ASTM D976. This increase will assure better cold starting, reduced smoke opacity, faster warm-ups, improved engine power performance, and increased mileage.

PROTECTION FROM BIODIESEL BLENDS: Hill Diesel Fuel Additive is 100% synthetic and will protect and revitalize seals, rubber components, and protect the fuel system from stiction and sludge build-up.

FUEL STABILIZATION/OXIDATION STABILITY (STORAGE) - AST TEST D2274

Expected life of diesel fuel is indicated by oxidation stability test D2274. This test measures how much gum and sediment will be deposited after keeping the fuel at 95°C in the presence of oxygen for 16 hours (corresponds to approximately 1 year storage at 25°C). A result of less than 20m/L of sediment and gum after the test is considered acceptable to normal diesel.

After 1 Year Storage

20 me/L

3 mg/L

RESULT: Treating with Hill Diesel Fuel Additive resulted in 85% less gum and sediment after 1 year of storage.

CETANE NUMBER - AST TEST D976

Cetane number (CN) is a measurement of the combustion quality of diesel fuel during compression ignition. The higher the CN, the more easily fuel will combust in a compression setting (such as a diesel engine). The characteristic diesel "knock" occurs when the first portion of fuel that has been injected into the cylinder suddenly ignites after an initial delay. Minimizing this delay results in less unburned fuel in the cylinder at the beginning and less intense knock. Therefore higher-cetane fuel causes an engine to start more easily, run smoother and quieter, as well as increasing power and mileage.

RESULT: Cetane improved over 4 numbers when treated with Hill Diesel Fuel Additive.

CORROSION PROTECTION - AST TEST D130

Evaluates the degree to which a lubricant will corrode copper-containing materials (i.e. bronze, brass)

- Rates oils by immersing a prepared copper strip in a lubricant at 2 temperatures in typical range of operation.

- Ratings range from "1a" with slight discoloration, but barely noticeable (similar to a freshly polished strip), to "4c" or severely corroded, blackened or pitted.

ASIM Copper Strip

Corrosion Standards

ASTM COOPER STRO CORPOSIY STANDL

RESULT: Hill Diesel Fuel Additive received the rating of 1a

CORROSION RATING (NACE STANDARDS) - TEST FOR FERROUS METALS

Shows the rating from E (poor: 75-100% coated with rust) to A (excellent: 0% rust) of the ability to resist corrosion, per NACE standards. NACE International is the world's leading professional organization for the corrosion control industry.

RESULT: Hill Diesel Fuel Additive received the rating of A for resistance, vastly improving fuel's corrosion resistance.

ANTI-GEL/POUR POINT - ASTM TEST D6371

Diesel engine power loss during winter is often traced back to Paraffin crystal formation restricting flow through fuel filters.

Freezing temperatures can also cause emulsified water to form a fuel/ice slush.

Pour point is the temperature at which the Paraffin in fuel crystallizes to the point where fuel gels and resists flow.

RESULT: Pour Point improved (reduced) by -22°F when Hill Diesel Fuel Additive was added to #2 diesel.