FREE SHIPPING - LOWER 48

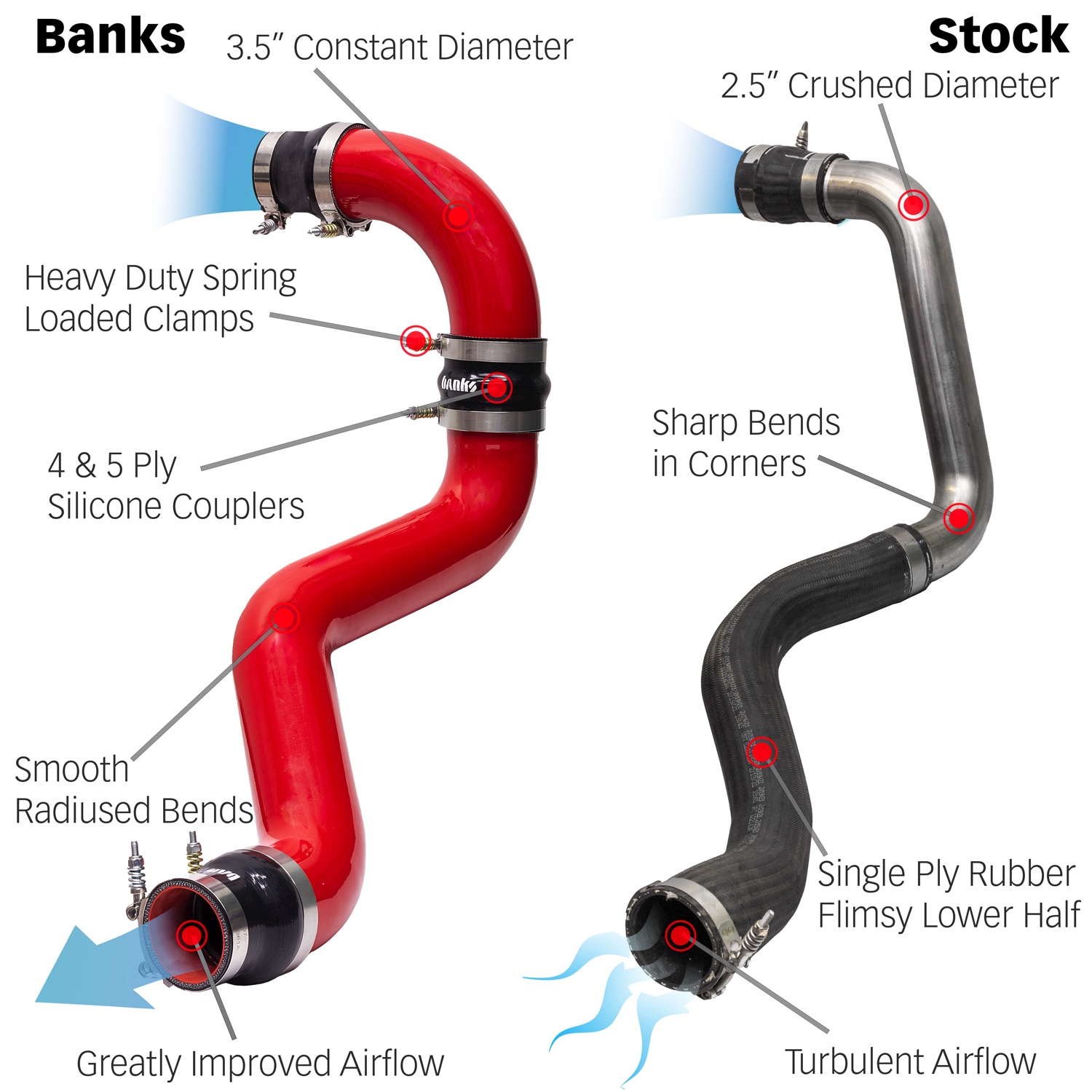

Banks massive 3.5" boost tubes are the largest on the market, flowing 26-45% more air than stock! Smooth mandrel-bent tubes deliver more air to your engine while reducing boost pressure loss resulting in quicker turbo spool and more power.

BANKS BOOST TUBES FLOW BEST

Banks oversized charge air cooler pipes and pair of unique billet adapters results in less boost pressure loss from turbo to intake manifold.

With an 26-45% improvement in airflow, your turbo can spool faster and sustain boost pressure with less wasted energy and heat.

Banks Boost-Tubes allow your engine, and specifically your turbo, to work less hard in compressing intake air; this maximizes horsepower delivery and throttle response while reducing engine stress.

INDUCTION PERFECTION

Even with the tighter engine space in the 2020+ L5P, Banks engineers were still able to maintain a full 3.5" diameter on both the hot and cold side of our boost tubes.

Put up side by side with the factory intercooler piping, ours could practically eat the stock one whole!

The combination large smooth mandrel bends and steel construction put the Banks Boost-Tubes in a performance and durability class of their own.

GOING THE EXTRA MILE

GM revised, moved, and updated several components throughout the engine bay for the 2020+ L5P, including a new coupler system on the cold side.

Our engineers used CFD simulations to design a pair of billet couplers for both ends of the cold side tube with a perfect taper and unique double parabolic shape to maximize airflow and reduce airflow restriction.

The shape and curvature of these couplers are critical to maintaining pressure efficiency throughout the intercooler system.

DO IT RIGHT

For the 2020+ L5P, GM decided to go with a near full rubber hose design on the cold side.

While this design might have simplified production for GM, its added flex and hose swelling leaves potential performance on the table.

Built from mandrel bent steel, Banks Boost-Tubes will never flex, crack, or dry out like the OEM Charge Air Pipes. They are built to resist clamping force deformation and other stresses for unparalleled durability and strength.